Environment

Introduction of Rotor Sail (Wind propulsion system)

MOL Techno-Trade, as an agent of Norsepower, wants to share some information about Rotor Sail technology and experience from current installations.

Rotor Sail technology

Norsepower’s Rotor Sail solution is a modern auxiliary wind propulsion system that reduces a ship’s fuel consumption and related emissions. The Rotor Sail produces a thrust force by the Magnus effect, which creates a pressure difference around the spinning cylindrical rotor when wind conditions are favorable. The pressure difference causes a lift (thrust) force perpendicular to the wind direction. This thrust force reduces the thrust and power requirement from the main propeller and reduces fuel consumption and related emissions.

Reduction of fuel consumption and emissions is typically 5-20% on average depending on ship type, wind conditions, time at sea, and the number of Rotor Sails installed.

Reference ships in operation with Norsepower’s Rotor Sails

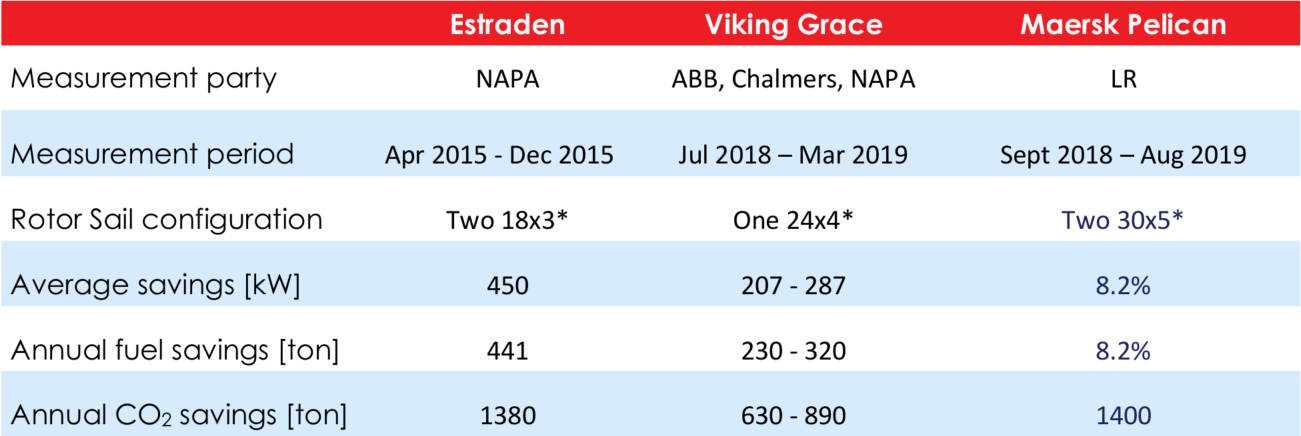

- The first pilot installation with two model 18x3 Rotor Sails on the RORO-vessel "Estraden" has been in operation since 2014.

- The installation of one model 24x4 Rotor Sail on cruise ferry "Viking Grace" was completed in April 2018.

- The third installation was completed in the end of August 2018 on the "Maersk Pelican", a 109 000 DWT LR2 tanker owned by Maersk Tankers.

The fuel-saving performance of the Rotor Sail installations on each of these reference vessels has been measured and analyzed by independent third-parties.

* Rotor Sail models are coded by the height (18, 24 or 30 m) and the diameter (3, 4, or 5 meters) of the spinning rotor.

Next delivery project

The fourth ship with a Rotor Sail installation will be the hybrid ferry "Copenhagen" owned by Scandlines . One model 30x5 Rotor Sail is expected to reduce fuel consumption and emissions by 4-5% on average.

Classification rules and approvals

Many classification societies have guidelines for the design and implementation of wind propulsion systems on ships. Lloyd’s Register has approved the installations on the first three vessels with Norsepower’s Rotor Sails. DNV GL has issued a Design Type Approval Certificate for the largest Rotor Sail model (30x5). Norsepower works together with the classification societies to ensure compliance with applicable rules and requirements.

How much could Rotor Sails save fuel and reduce emissions on your ships?

Norsepower prepares simulation case studies to estimate the potential for fuel-saving on specific routes or in average global wind conditions. If you would like to see how much fuel costs and emissions can be reduced by installing Rotor Sails on one or more of your ships, please be in touch with pbcf@motech.co.jp.

Can Rotor Sails on ships make a difference?

IMO’s target of reducing the CO2 emissions of shipping by 50% by 2050 requires combining a variety of technologies and solutions, improving the energy efficiency of ships and increasing the share of renewable energy in ship operations. Norsepower has prepared an estimate of Rotor Sail technology’s potential for reducing the CO2 emissions of global shipping. By installing wind propulsion and specifically the Rotor Sails on the worldwide fleet can reduce an estimated 82 million tons (8%) of the CO2 emission of shipping.

The calculation of the total carbon footprint of Rotor Sails indicates that the CO2 emissions produced in the manufacturing of a Rotor Sail are recovered within 2-4 months of operation on a ship sailing in average global wind conditions. Therefore the overall emission reduction performance during a 20-year design life of a Rotor Sail is extremely positive.

Every ship has potential

Every ship has the potential to reduce environmental impact by improving the energy efficiency of existing equipment or installing new energy-saving equipment. Norsepower’s Rotor Sail technology is an environmentally and economically sustainable solution suitable for most ship types. Maintenance requirements are very low, and operation is fully automated with remote monitoring and service support available from Norsepower. Contact us to find out how much savings are achievable in your fleet.

Norsepower provides additional information on their website, please visit

We are looking forward to having the opportunity to contribute your eco action.